#ImpactacademyofficialFree Engineering Video Lectures.👍👍👍For More Videos Click On Playlist Link Shown Below ↓ Metrology : https://www.youtube.com/playl.. Go/no-go gauges. Go and no-go gauges. Go/no-go gauges are encountered in all types of manufacturing. They may measure a physical dimension, e.g. (50 ±0.01mm), or a value such as the value of a resistor (100Ω ±1%). A typical example is a plug gauge. See also. Gauge block; Qualitative property.

GO/NOGO GAUGE 금창정밀

Go / NoGo Gauge A Lean Term from the awardwinning Continuous Improvement Companion

Clymer Go/NoGo Gauge Set .308 Winchester GONG308WIN

GONOGO Gauge for DMC Crimpers

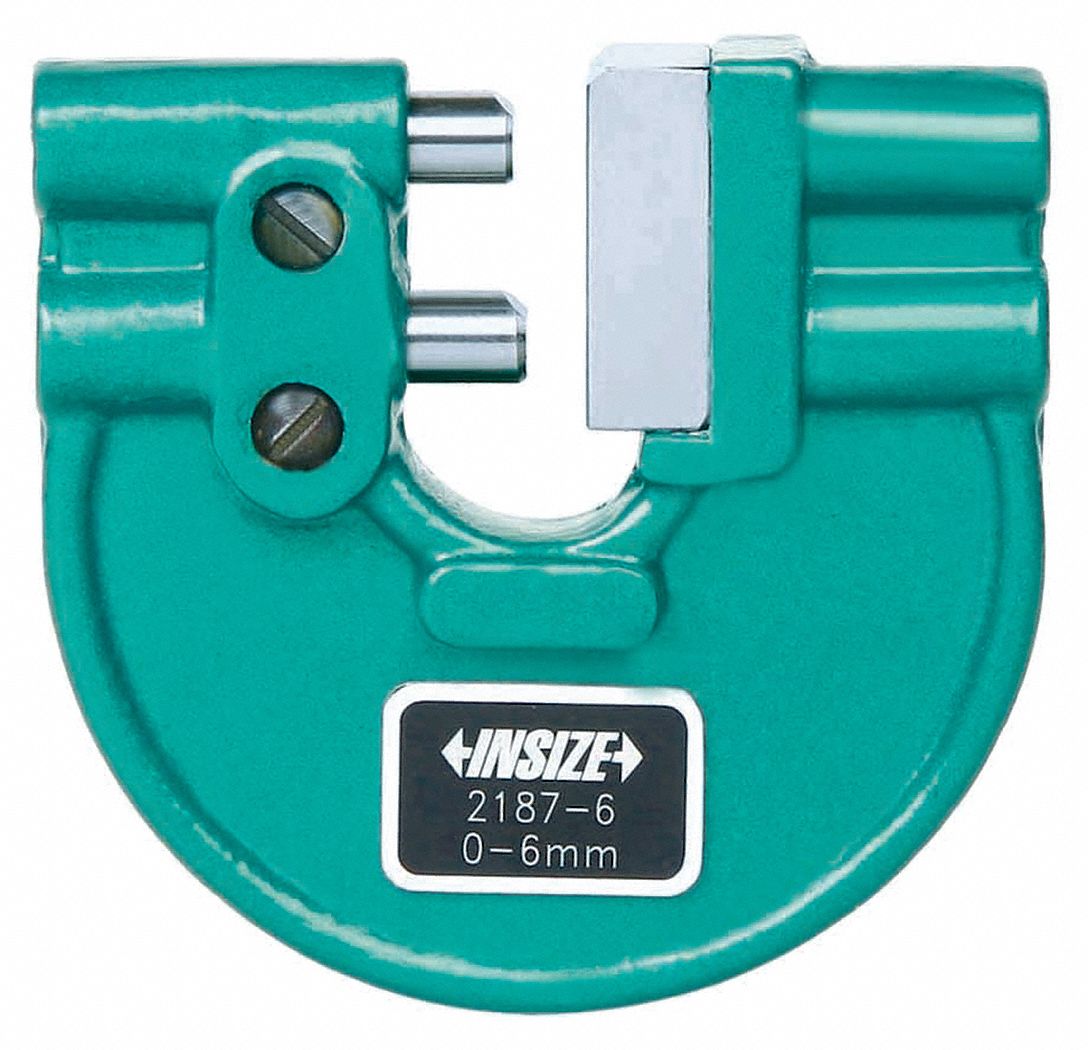

INSIZE Adjustable Go/NoGo Snap Gauge, Measurement Style Go/NoGo Gauge Limit Setting 55VN16

GoNoGo Gauges Lot of 29 339594 For Sale Used

GO/NOGO GAUGE 금창정밀

Lot of 30pc GOnoGOGauges Mixed sizes Chicago HVAC tools and supplies

Pinewood Derby Wheel Go/Nogo Gauge Maximum Velocity

M4 x 0.5 Pitch 6H Steel Go/No Go Plug Thread Gage Gauge Amazon.co.uk DIY & Tools

M36 x 4mm Metric Coarse Go/NoGo LH Plug Gauge 6H (JBO) Cutwel Gauge Supplier

Manufacturing Archives SMLease Design

Plain GO/NO GO Ring Gauges Piramyd Precision

Go and NoGo Gauge Example, Types, Advantages and Limitations

Go and NoGo Gauge Example, Types, Advantages and Limitations

Go GAUGE & NOGO GAUGE 通止規說明

Lot of 30pc GOnoGOGauges Mixed sizes Chicago HVAC tools and supplies

GO and NOGO Gauge GaugeHow Mechanical Engineering

M22520/301. Daniels GAUGE, GO/NOGO, GREEN/RED element14 Korea

Dasqua Thread gauge Set (plug gauge) M3 M12 Go and No Go SORRY OUT OF STOCK Chronos

Go/No Go Gauges. Go/No go gauges are tools used to check the tolerances of a workpiece, for example, thread depth and major diameter of a screw. Go/no go gauges are utilized to ensure interchangeability of parts between processes. Go/no go gauges rate a component as either acceptable (within tolerance), or outside of tolerance.. January 1, 2018. The basic concept of a thread plug is to provide a quick inspection for machinists and quality inspectors to verify that the threads are within the accepted tolerance so that it interacts with the mating part correctly. This verification would be performed by threading the Go thread gage to the full depth of the feature without.